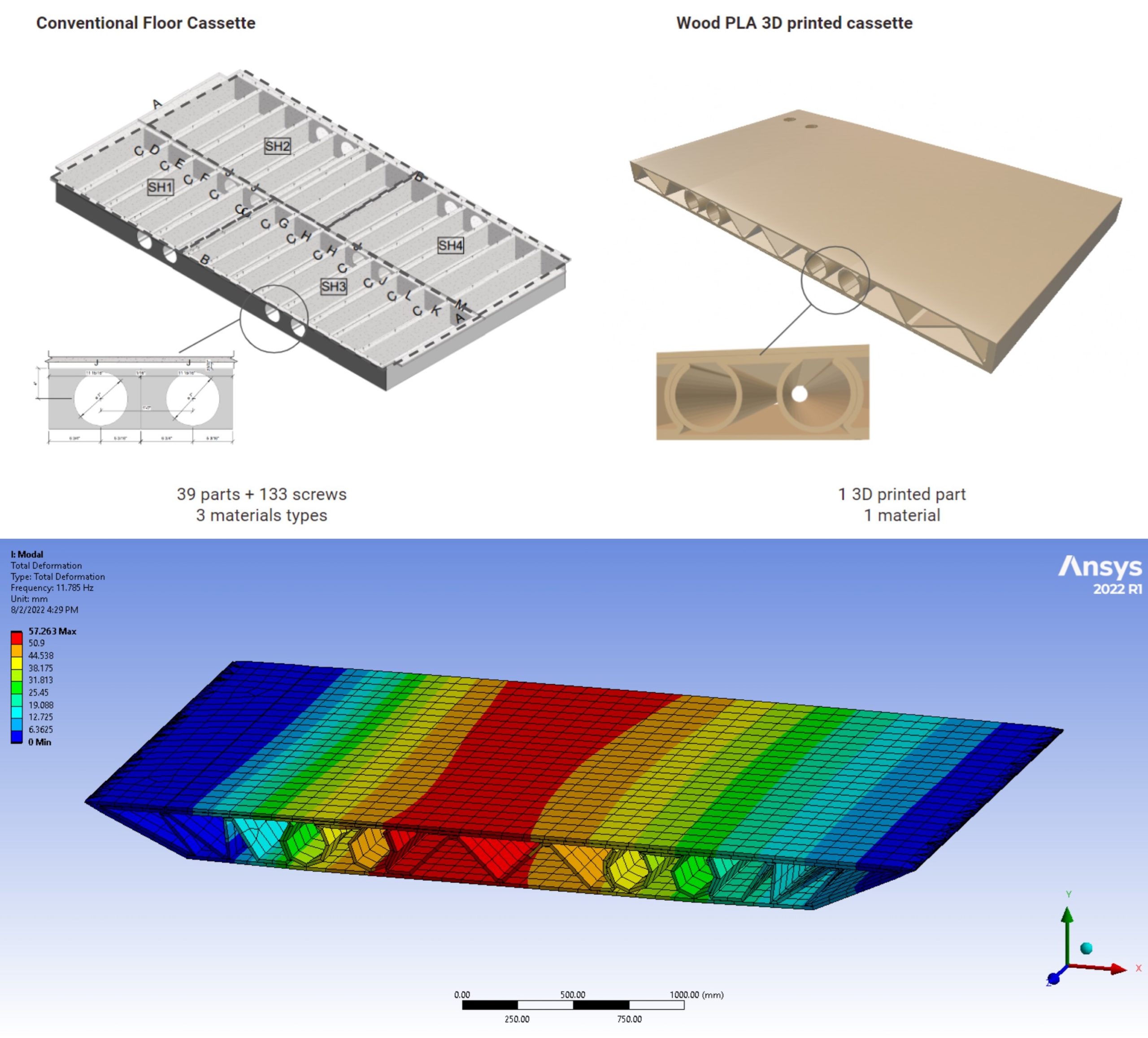

Researchers at the University of Maine have released images of the 3D-printed, natural-material floor cassette they say is strong enough to replace steel-and-concrete floors in multi-storey buildings.

The university worked with the US Department of Energy’s Oak Ridge National Laboratory (ORNL) to develop the “SM2ART Nfloor cassette”.

It’s made from a mix of polylactic acid (PLA) – a biodegradable thermoplastic derived from corn residue – and wood flour from lumber-processing waste.

“The PLA and wood flour blend is an excellent material for producing recyclable, large-format additively manufactured parts,” said Scott Tomlinson, structural engineer with the University of Maine’s Advanced Structures and Composites Center (ASCC).

“This single-piece floor assembly is stiffer and provides an improved walking experience when compared to the steel-concrete assembly it replaces,” he added.

ORNL researcher Katie Copenhaver said: “By utilising bio-based, large-scale 3D printing, we replaced an assembly made from 31 parts and three materials with a single-material floor panel that is ecologically friendly and with the same strength as traditional steel floor fabrication.”

Labour-saving

The printer laid down layers for the geometrically-shaped cassette in about 30 hours, which researchers said represented a labour saving of about 33% compared to building a traditional floor.

It was programmed to leave openings for electrical, plumbing, and ventilation services.

Researchers said a big part of the cost of traditional floor construction comes from workers cutting such openings retrospectively.

“3D printing can save time and money by printing the floor cassette with cutouts designed into the finished product,” said Copenhaver. “The only human labor involves installing acoustic skin for sound proofing and the resident’s desired floor covering.”

The cassette is fully recyclable, according to the researchers.

SHoP Architects’ idea

The idea for the project came from New York City-based SHoP Architects.

“They asked if we could mass-produce floor panels more efficiently with greener materials and additive manufacturing,” said Copenhaver.

“Figuring out something new, considering different variables, is a hallmark of ORNL. Through experimentation, we worked out the right speeds and made the tweaks needed to reliably produce a finished part with the desired finished look and quality.”

Research moves now to flame retardants, insulation, and better production techniques.

UMaine’s Scott Tomlinson said the technology “holds a lot of promise for the future of sustainable buildings”.

- Subscribe here to get stories about construction around the world in your inbox three times a week

More on alternative materials: