A robot that can tie up to 1,100 rebar intersections an hour is being used on the $598m Gateway Expressway Project in Clearwater, Florida

The project entails adding two new, four-lane elevated tolled roadways and connections, BIM+ reports.

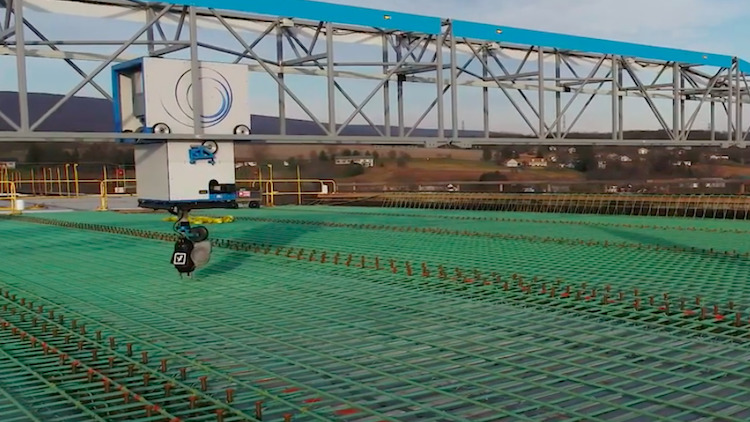

The brainchild of a US civil engineering company boss who struggled with labour shortages, the ‘TyBot’ uses a robotic arm rigged to a gantry crane to find rebar junctions and attach a tie before a concrete pour, saving many hours of back-breaking labour on road, bridge and other projects.

It works “continuously, day or night, rain or shine, without breaks or injury”, says its developer, Advanced Construction Robotics (ACR).

Equipped with machine vision and learning, it self-navigates its working area and requires no pre-mapping or calibration, according to ACR. It can be assembled in up to four hours by two workers and a crane operator.

- See TyBot on the job:

Once assembled, it requires one supervisor to monitor performance, reload the tie wire spool when necessary, and ensure the robot does not impede site safety.

Construction and rebar contractor Shelby Erectors has already used TyBot in earlier stages of the Gateway project, completing more than 275,000 deck ties across an 81,750 sq m bridge deck.

Boring robot

TyBot developer ACR was created in 2017 by Stephen Muck, owner and chief executive of Brayman Construction Corporation, a national civil contractor headquartered in Pittsburgh, a global hub for robotics research.

With labour shortages causing Brayman pain in road and bridge jobs, and with rebar tying being the most labour-intensive part of those jobs, Muck got the idea for the TyBot during a presentation on the latest robotics technology. He set up ACR with experts in motion control, artificial intelligence, electrical, mechanical and hydraulics engineering to develop a prototype.

ACR figures have joked that TyBot is quite boring as a robot, but Muck estimates that it can save up to 50% of the bridge-deck rebar labour function.

In 2018, ACR announced that its subsidiary, TyBot LLC, had closed a $4m funding round, with investors including other heavy civil contractors, equipment dealers, and even a labour union.

Image: TyBot in action (Courtesy of Advanced Construction Robotics)

Further reading:

Comments

Comments are closed.

Great innovation for a specific type/task of rebar-tying.

If no “mapping or calibration” is required, it may be worth noting that normal people are required to load and accurately place the rebar and construct the formwork before the Robot Team can commence their setting up and the setting-to-work of the Robot.

As good as it all is (and it is); are we losing sight of the versatility of a well trained, suitably motivated workforce (human beings) ?

Awesome, good thinking and innovative, future is robotics