A team of Swiss scientists and architects has created a bricklaying robot that is capable of working on a construction site in much the same way as a human worker: it can follow a plan, respond to late design variations and deal with random events such as obstacles in its path.

I think that in the next five to 10 years we are going to see mobile robots on the construction site, but they’re not going to replace humans. They’ll actually collaborate with humans, so the best of each kind of skills come together– Jonas Buchli, Swiss Federal Institute of Technology

The In-situ Fabricator has been developed by the Digital Fabrication branch of the Swiss National Centre of Competence in Research (NCCR) in Zürich. Matthias Kohler, an architect who is also the director of the centre, told Reuters the robot was “the first machine that can actually go on construction sites and build non-standard designs, meaning designs that can vary and adapt to the local conditions”.

The robot is made up of an articulated arm moved around by caterpillar tracks. It is controlled by two computers, one of which handles bricklaying and another that moves the unit around the site and uses information from a laser rangefinder and computer algorithms to build up a 3D map of its surroundings.

Jonas Buchli, a professor at the Swiss Federal Institute of Technology, said construction sites were interesting environments for roboticists. “They are somewhere in between the completely planned and controlled environment of a factory or a lab floor and the chaotic environment of outdoors, so they are kind of a semi-structured environment where we can test and develop the technology that is required for robots to move around and do useful things,” he said.

As well as its distance-measuring sensors the robot will carry cameras and be fitted with an “inertial measurement unit” similar to the chip fitted in smart phones that detects orientation. Â

Kohler said the robot was attractive to architects because it created a more direct link between the design and the finished building.

He said: “The benefit from an architectural point of view is that you can really design the construction directly, so you can plan for how it is built instead of designing your plan and then that plan afterwards being converted on the construction site. So it actually changes the paradigm of how you design and build quite fundamentally.”

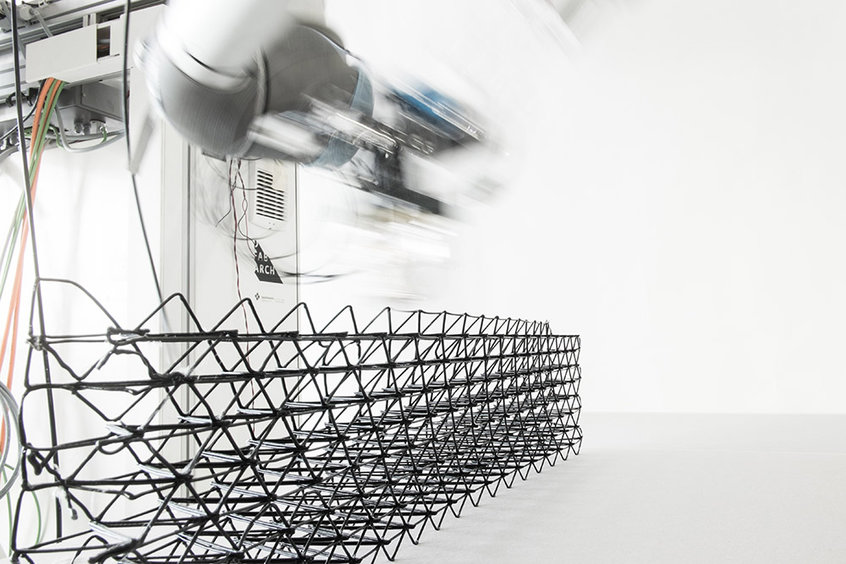

Another research project is computerised concrete formwork know as Mesh Mould (Architecture and Digital Fabrication, ETH Zurich)

He added that that did not mean that human bricklayers would be put out of business. “I think this will become a game-changer in construction,” he said. “I think that in the next five to 10 years we are going to see mobile robots on the construction site, but they’re not going to replace humans. They’ll actually collaborate with humans, so the best of each kind of skills come together.”

As well as the autonomous robot, the NCCR is working on a range of construction-related projects.

One involves developing robots that can fit together rubble to make a free-standing structure, and another called “Mesh Mould” (pictured), in which robots use 3D printing to form reinforcement meshes can be filled with concrete, eliminating the need for formwork.

A state-of-the art robotic fabrication lab that will allow NCCR to expand is due to open in September 2016.

The NCCRs are research agencies of the Swiss National Science Foundation. They promote long-term interdisciplinary research networks in areas of strategic importance for the future of Swiss science, economy and society.

Comments

Comments are closed.

In your dreams!

great hope it knows how to mix its own concrete!

Make these technologies responsible for the results to creating robots to replace humans by requiring the manufacturer to retrain a percent of those it replaces and train these in repaing these robots when they break down.