Commercially viable wind turbines usually reach only 100m in height because of a mundane logistical restraint.

Now, three companies have teamed up to double that height with 3D printing in order to reach stronger winds.

GE Renewable Energy, cement giant LafargeHolcim and the Danish printed structures company Cobod have agreed to develop printed pedestals that support 200m-tall turbine columns.

In the coming years they aim to produce a wind turbine prototype with a printed pedestal, as well as the necessary type of printer and materials.

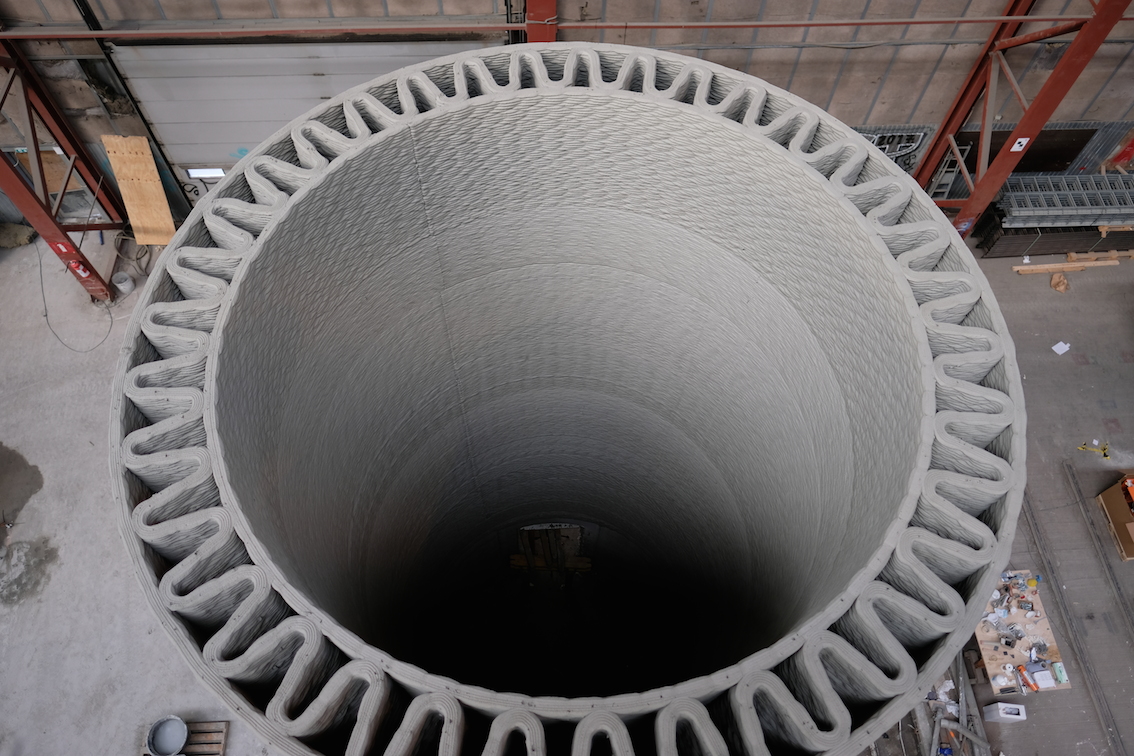

Cross-section of the prototype shows design of the printed structure (Cobod International)

The first prototype, a 10m-high pedestal, was successfully printed in October 2019 in Copenhagen.

Making turbines taller would allow them to capture stronger winds, thereby generating more renewable energy per turbine, the partners said in announcing the initiative today.

At present, turbine towers build of steel or precast concrete are typically limited to under 100m because the width of the base cannot exceed the 4.5m diameter required for transport by road, without incurring excessive additional costs.

Printing the base on site removes that restriction.

- Watch the structure being printed here:

Â

Going higher will generate more electricity, the partners say.

Typically, a 5MW turbine at 80m generates 15.1GWh in a year, while the same turbine at 160m would generate 20.2 GWh, which is 33% more.

GE Renewable Energy will advise on the design, manufacture and commercialisation of the super-tall turbines, Cobod will advise on the robotics of the printing and LafargeHolcim will design the tailor-made concrete material.

“Concrete 3D printing is a very promising technology for us, as its incredible design flexibility expands the realm of construction possibilities,” said Edelio Bermejo, Head of R&D for LafargeHolcim.

Cobod founder Henrik Lund-Nielsen said he was “convinced that this disruptive move within the wind turbines industry will help drive lower costs and faster execution times, to benefit customers and lower the CO2 footprint from the production of energy.

“Concrete printing has advanced significantly over the last five years and we believe is getting closer to have real application in the industrial world,” said Matteo Bellucci, Advanced Manufacturing Technology Leader for GE Renewable Energy.

Top image: The first prototype, a 10m-high pedestal, was successfully printed in October 2019 (Cobod International)

Further reading: