Work has started on a factory in the south-eastern Chinese province of Guangdong in which nine out of every 10 workers will be a robot.Â

The Evenwin Precision Technology plant in the city of Dongguan exemplifies the “zero labour” concept. When completed, it will have a robot assembly line overseen by 200 software technicians and managers, who will assist the robots by running the operating system and managing the commercial side of the operation.Â

Evenwin, which makes electronic components for other industries, said it plans to staff its factories with some 1,000 robots that will do the work of 1,800 labourers. According to the company, the factory could reach an annual production capacity of $322m.Â

Workshop running out of workersÂ

Much of the Chinese economic miracle has been based on the exploitation of cheap labour in the vast factories of the Guangdong manufacturing hub, which has thereby picked up the title of “workshop of the world”.Â

However, there are signs that the labour supply, which was based on the urbanisation of rural workers, is drying up as standards of living increase and better paid work becomes available. This is despite the fact that the average factory worker in China earns an average of $500 a month, compared with $350 in Thailand and $75 in Cambodia.Â

According to the Guangdong Department of Human Resources and Social Security there is currently a shortage of 600,000 to 800,000 workers in the emerging Pearl River Delta megacity, which has become the largest urban area in the world in terms of size and population.Â

In Dongguan, 505 factories have spent almost $700m on replacing more than 30,000 workers with machines since last September, according to the city’s Economy and Information Technology Bureau.

By 2016, as many as 1,500 of the city’s industrial centres will start replacing humans with robots, and Guangdong’s authorities have said that $152bn will be invested in robotics by 2018.

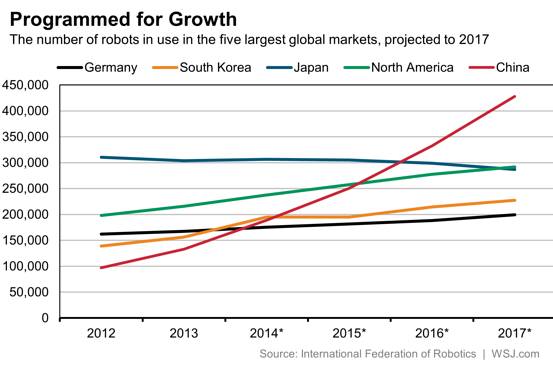

The number of robots in use in the five largest global markets, projected to 2017 (International Federation of Robotics/WSJ.com)

Guangzhou, the capital of Guangdong, has a goal of growing the robot workforce to a productive capacity of $16bn by 2020, and plans to automate around 80% of the city’s manufacturing production. Â

Our robot overlords?Â

In the whole of China, 32,000 robots worked in manufacturing in 2013, and new robots made up 20% of worldwide installations that year. However, China is playing catch-up with the other highly advanced manufacturing countries. Its robot-to-human ratio of 30 per 10,000 employees is lower than Germany’s 282, Japan’s 323 and South Korea’s 396.Â

Despite this China is due to have more factory robots than any other country by 2017 (pictured).Â

Manufacturing industry around the world is undergoing a fourth industrial revolution as factories spend less on upgrading equipment and focus instead on high-tech systems such as sensors, 3D printing, data science, robotics and increasingly sophisticated automation based on machine-to-machine communication.Â

Employers in this sector will look for employees who can handle data and analytics, but there will be a decline in traditional assembly line jobs.Â

Startup company CloudDDM opened America’s first 3D printing factory this week. It will manufacture machine parts and prototypes, but will only employ one worker a shift, who will oversee 100 printers.Â

In the meantime, for the rest of the human workforce there is a list of occupations ranked by automatability.Â

Image: Robots on a production line at the Ford Motor Company assembly plant in Louisville, Kentucky in April 2015 (Luke Sharrett/Bloomberg/Getty Images)