Nanyang Technological University (NTU Singapore) scientists have invented a new type of bendable concrete that is stronger and longer lasting than what we use today.

So-called “ConFlexPave” allows for the creation of slim, precast pavement slabs that can cut the time needed for road works and new pavements in half, they say, adding that the new material needs less maintenance.

NTU Professor Chu Jian said: “We developed a new type of concrete that can greatly reduce the thickness and weight of precast pavement slabs, hence enabling speedy plug-and-play installation, where new concrete slabs prepared off-site can easily replace worn out ones.”

How it works

New concrete slabs prepared off-site can easily replace worn out ones– NTU Professor Chu Jian

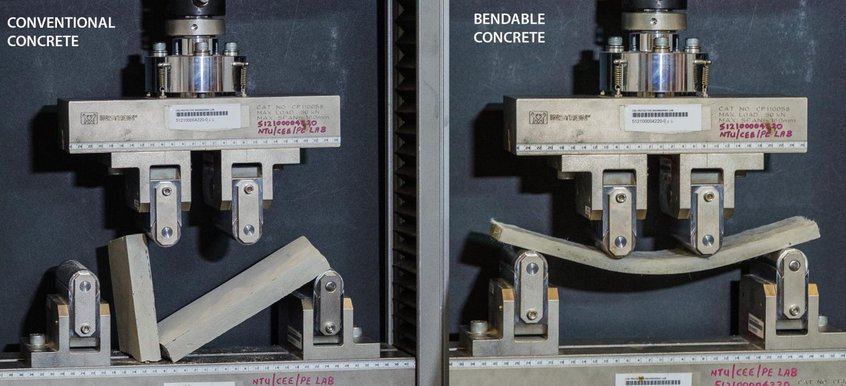

Traditional concrete comprises cement, water, gravel and sand. This makes concrete hard and strong, but also brittle.

ConFlexPave mixes hard materials with polymer microfibres, which allow the concrete to flex under tension. Researchers say it also enhances skid resistance.

Tablet-sized slabs have been successfully tested as at NTU laboratories, and tests will be scaled up for vehicular traffic over the next three years, in partnership with JTC Corporation, Singapore’s state developer of infrastructure technology.

Microscopic level

The breakthrough was understanding how the components interact on a microscopic level, said Assistant Prof Yang En-Hua from NTU’s School of Civil and Environmental Engineering, who led research.

Polymer microfibres distribute the load across the whole slab, scientists say (Nanyang Technological University)

“With detailed understanding, we can then deliberately select ingredients and engineer the tailoring of components, so our final material can fulfil specific requirements needed for road and pavement applications,” said Prof Yang.

“The hard materials give a non-slip surface texture while the microfibres which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in a concrete that is tough as metal and at least twice as strong as conventional concrete under bending,” he added.

The government hopes the new concrete will save time and resources.

“JTC hopes to pioneer cutting-edge industrial infrastructure solutions to address challenges faced by Singapore and its companies such as manpower and resource constraints,” said Koh Chwee, director of the technical services division of JTC.

“We will continue to open up more of our buildings and estates to test-bed and if successful, implement such new solutions.”

- See more here.

Top image: NTU Asst Prof Yang En-Hua holding the bendable concrete developed by his team (Nanyang Technological University)

Comments

Comments are closed.

Money well spent in engineering a concrete exactly compliant with the properties required for its intended use! This trend in modifying of the whole range of our customary building materials to improve their natural properties is ongoing world wide and is achieving increasing success!

A fascinating article which challenges the traditional way in which we think about construction materials. Will be interesting to see how this develops.

Wonder what the applications of this new bendable concrete are for the wider concrete family, in particular for sprayed concrete (or shotcrete)? It is often mixed with fibers in order to reduce the need for other reinforcements like bolts or steel mesh in underground mining and tunnelling. Any thoughts welcome.

Sounds like the perfect building material for earthquake prone areas.

never mind pavement + loaded 6-wheelers weighing on top 24h/day.Considering individual house-oriented possible uses, no more wall/floor cracks, any swimming pool shapes,strong wind-resistant mobile PV surfaces, private ways through parks/gardens etc. It could become one major breakthrough, sans vouloir faire de jeux de mots !