Engineering firm Arup has found a way of 3D-printing steel nodes for use in complex structures which, it says, could cut time and cost in the design and manufacture of lots of individual components.

Using the latest 3D printing techniques – or ‘additive manufacturing’ – Arup has produced a design method for structural steel elements, and a printed prototype of a complex node.

The prototype is currently more expensive to produce than a traditionally manufactured one, but the company says the work signals a whole new direction for the use of additive manufacturing in engineering, and that it has the potential to cut costs, waste and carbon in the construction of complex structures.

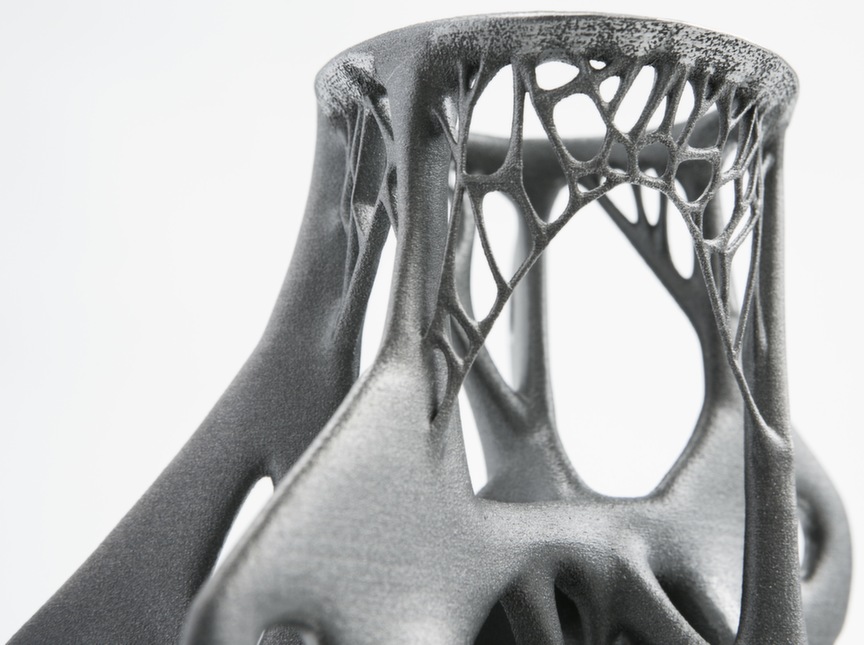

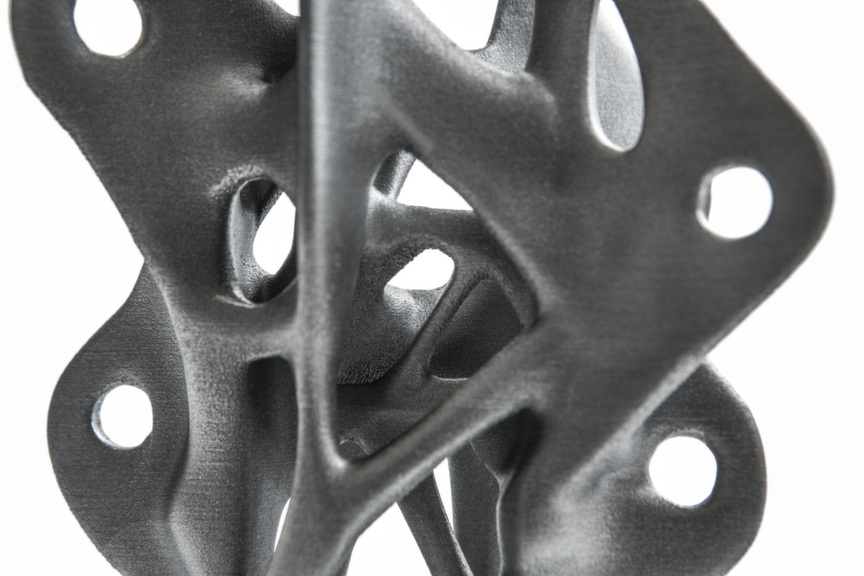

There is still work to be done in reducing the node’s weight without compromising its strength, Arup says (David de Jong/Arup)

“By using additive manufacturing we can create lots of complex individually designed pieces far more efficiently,” said Salomé Galjaard, a product designer and leader of the research project at Arup. “This has tremendous implications for reducing costs and cutting waste. But most importantly, this approach potentially enables a very sophisticated design, without the need to simplify the design in a later stage to lower costs.”

In an interview with GCR, Galjaard said Arup began researching the idea around a year and a half ago, starting with an open set of questions including whether anyone was looking into this application of additive manufacturing already. Finding none, Arup decided to fund the research and work with others including WithinLab, an engineering design software company, additive manufacturing firm CRDM/3D Systems, and EOS, an additive manufacturing pioneer.

Up to 1,200 different configurations for the prototype were designed (David de Jong/Arup)

Galjaard said the team learned much about the designing-for-print process and that up to 1,200 different configurations for the prototype were designed. The node’s weight could be reduced even further, she said, without compromising its ability to handle the required loads.

The results have been publicised only in the last few weeks internally at Arup, and Galjaard said the news generated a lot of comments.

She said there was much more development to be done before “printed” structural nodes were used in buildings, but that the next step could be using them in large sculptures.