A German team has built a warehouse in Stuttgart with load-bearing concrete walls using a continuous 3D-printing process.

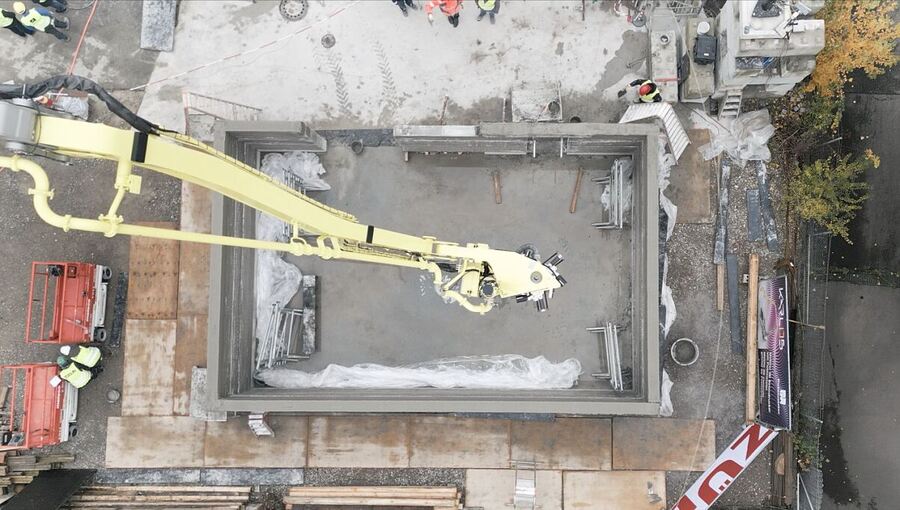

The structure, which the team describe as a “world first”, was created using a truck-mounted concrete pump that is able to spray 26m of carbon-reduced concrete across multiple layers in a single operation.

The technology, which is called Karlos, offers an alternative to gantry printers.

The building was built by Züblin, the German subsidiary of Austrian contractor Strabag, together with Putzmeister, a subsidiary of Chinese equipment maker Sany.

Christoph Kaml, Putzmeister’s chief executive, said: “A high degree of electrification and automation is required along the entire work process. The reduction of manual labour is a decisive factor in dealing with the increasing shortage of skilled workers.”