The developer wanted an iconic art installation designed by famous artist James Turrell, but it had to be made with timber. The project team were sceptical at first, but here, Kevin Hill MCIOB, managing director of Singapore-headquartered engineered timber specialist Venturer, describes how they worked with an award-winning architect to conquer the complexity required to deliver pure simplicity.

It was the developer’s vision to include iconic art pieces within the Fari Islands Development, comprising a Ritz Carlton and Patina Hotel, the largest luxury hospitality development undertaken so far in the Maldives.

World-renowned American artist James Turrell, known for his installations giving experiences of light and space, was commissioned to create his iconic “Skyspace”, his first installation in the Southern Hemisphere. The owner also wanted to use the latest engineered timber technology for the first installation of this kind in Asia, to make it carbon negative.

Award-winning Brazilian Architect Marcio Kogan, who leads Studio Mk27, was engaged to bring Turrell’s vision to life, and Venturer was appointed early in the design process to find the right delivery solution.

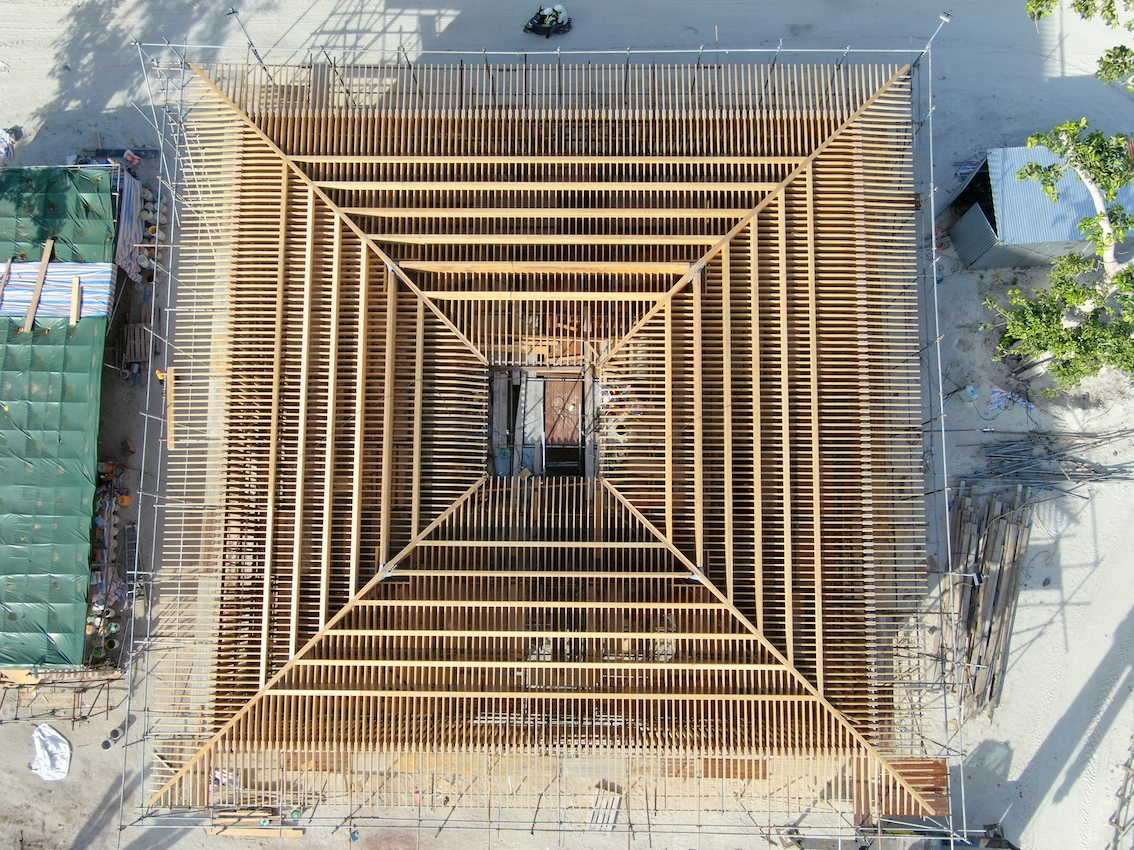

The design called for a 400-sq-m free span roof with razor-sharp soffits and a 16-sq-m hole in its middle. Although we work with some of the best timber engineers in the business, we doubted it could be done.

That’s because when you remove the centre of a free span roof it needs to defy gravity. If you think of iconic floating roofs such as that adorning Apple’s Apple Park campus in Cupertino, California – the biggest carbon-fibre composite roof in the world – they tend to have complex structures in the centre that radiate outward. But the design brief called for no visible beams or independent columns, inner supports or exposed connections.

Timber? Really?

Over certain spans, engineered timber’s strength to weight advantage diminishes so, with the owner’s blessing, we evaluated a variety of different material approaches, putting sustainability to one side for the purpose.

Other Skyspaces had relied extensively on steel sections, but steel in the corrosive marine environment of the Maldives is not ideal and site welding is typically not allowed.

Taking inspiration from Apple, we contacted a professor at MIT and commissioned a feasibility study on using composite technology. The centre opening was the biggest challenge, but the composite solution seemed to favour more support at the hips and less along the continuous edge of the facade trellis that was critical to the aesthetic.

Code compliance was another restricting factor. It was hard to find recognised design codes we could rely on in order to maintain the Professional Engineer’s endorsement required across the project.

Another restricting factor was uplift. The roof forms a 400-sq-m wing and the lightness of composite was a drawback. Lastly the proposed install methodology was based on large volumetric sectional components that were deemed hugely complex to ship and forward to site. Clearly, a flat pack solution was the most logical approach.

Yes, timber

Ultimately, we went full circle and back to engineered timber. A leading European timber engineer together with our manufacturing partners in Germany worked with us to conceive a solution.

We settled on an approach where each trellis member was assigned a corresponding roof member, the trellis was reinforced with a longitudinal timber edge beam and continuous longitudinal wedge.

Several continuous laminated veneer lumber (LVL) beams within the roof structure, along with the LVL roof surface, acted as diaphragm.

The resulting solution, designed within EuroCode 5, was found to be more efficient than composite or steel in terms of structural performance, visual aesthetic and the client’s budget.

Pulling it all together

Working with Studio Mk27, we designed all components for manufacture and assembly, allowing a kit of very complicated components to be put together on site.

A key challenge of the trellis was the need to tie all the members together in order for it to act as a shear wall, and to simplify the install process by allowing the panelisation of wall elements.

At the horizontal tie or connection between independent trellis components, we adopted a horizontal wedge comprised of 1mm-tolerance machined Borneo ironwood selected from an Indonesian forest certified by SVLK, the country’s timber legality assurance system. We believe this is the first time hardwood from the East has been used with engineered softwood from the West in an integrated structural solution.

Thousands of notches were precision machined by CNC machines at the factory, as were the steel drift pin holes. Finally, the diaphragm sheathing was screw-fixed to both outer surfaces, in effect constructing a profile similar to an airplane wing of old.

We calculate that the Skyspace, after production, shipping and assembly, has offset or sequestered around 100 tonnes of carbon, equivalent to taking 20 cars off the road for a year. If it had been built with steel and concrete, the carbon produced would likely be around 300 tonnes.