Five teams have won the latest stage of NASA’s competition for habitations that can be 3D-printed on Mars. They will now share a $100,000 prize, awarded by a jury of experts.

The designs for the third phase of the Habitat Centennial Challenge, which began back in 2014, required teams to construct building information models, or BIMs, of the habitats to prove that they would function in Martian conditions – as far as these are understood.

This means developing detailed designs for structures large enough to allow four people to live there for a year.

The BIMs will also have to take into account pressure resistance, heating and thermal insulation, structural strength, air filtration and energy generation.

The winning design, showing the white lander and its modules

The winning design was from Zopherus, an Arkansas-based team that plans to print its modules inside a large lander.

The idea is to have the lander crawl around the surface of the planet until it finds a level site. It then deploys rover robots to test the surface. When suitable materials are found, the lander seals itself to the ground to create a pressurised chamber.

When complete, it rises and moves a short distance to create another, a process that resembles a chicken laying an egg.

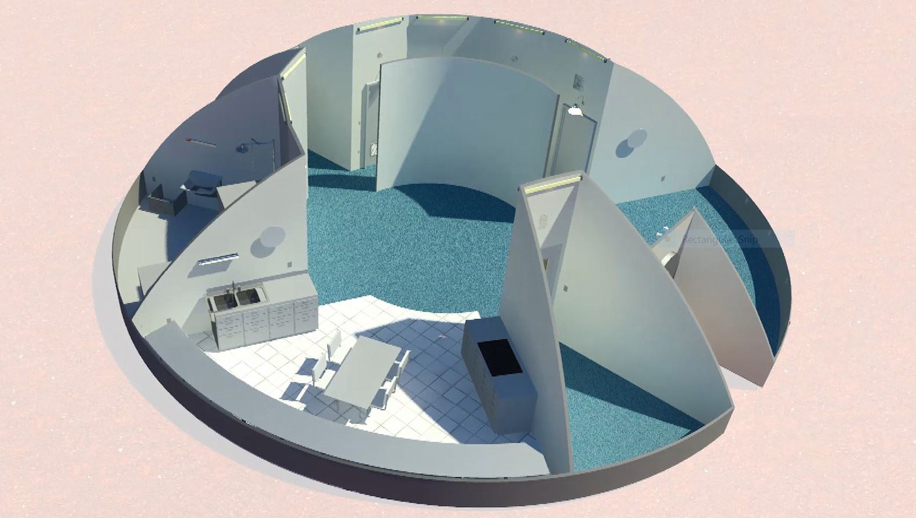

A vertical structure achieves the most efficient ratio between volume and surface area

The second-placed design is by AI SpaceFactory from New York.

Its Marsha (MARS HAbitat) is aimed at handling the difference between internal and external pressure – the Martian atmosphere is thought to be about one hundredth of the density of Earth’s.

It envisages a vertical egg-like container with a double shell and a minimal footprint. One advantage of the shape is that it avoids the need to move the printer in between modules.

The design would be made from a reinforced type of thermoplastic called PLA, which is recyclable has lowest coefficient of thermal expansion among plastics.

The spacious Kahn-Yates design, which New Atlas described as “incredibly ambitious”

Third place was Kahn-Yates of Jackson, Mississippi. This envisages a printed structural layer giving way to a high-strength plastic layer that lets the light in. This aerodynamic structure is optimised to deal with dust storms, and is large enough to contain a quarantine unit, laboratory and garden, as well as the services and living quarters.

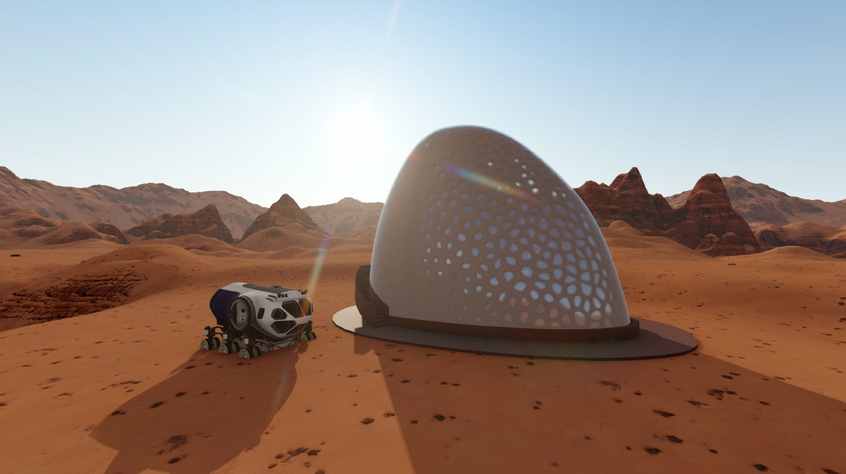

SEArch+/Apis Cor module has a dual habitat, one for sleeping, one for working

The team from SEArch+/Apis Cor of New York came up with the most striking aesthetic design. This horizontal egg contains two separate living areas, to build some redundancy into the design. The shape and orientation are intended to provide maximum protection from harmful radiation while making the most of what light reaches the fourth planet.

Northwestern University of Evanston’s design can be added to over time

Fifth place was taken Northwestern University of Evanston, Illinois. This proposes a spherical shell within an outer parabolic dome. Construction would be carried out by an autonomous robot printer, which would create a structure by spraying an inflated pressure vessel, which would then have the job of keeping the structure airtight.

Lex Akers, dean of the Caterpillar College of Engineering and Technology at Bradley University, NASA’s partner in this challenge commented: “The virtual levels allow teams from high schools, universities and businesses that might not have access to large 3D printers to still be a part of the competition because they can team up with those who do have access to such machinery for the final level of the competition.”

The next stage of the competition will require scale models of the designs will be built. Â

Top image: SEArch+/Apis Cor module has a dual habitat, one for sleeping, one for working

Further reading